Our expertise

You are here: Raigi > The company > Our Knowledges

Formulating epoxy, polyurethane and latex materials

Development and sale of elastomers in the following areas:

- Casting and injection moulding resins to protect underground cable junctions

- Casting and injection moulding resins for protection of electronic components by potting, particularly for the automotive market

- Casting elastomers for use in creating concrete moulds

- Injection moulding elastomers for producing a variety of polyurethane parts

- Natural gels as raticides and rat deterrents

- Casting elastomers for furniture applications

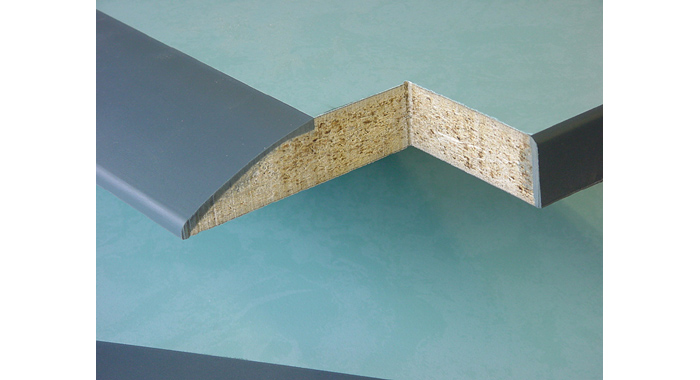

Development and sale of foams in the following areas:

- Flexible foams for producing parts like mattresses and different types of chairs

- Rigid foams as energy or impact absorbers, for insulation or as gap fillers

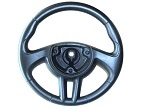

- Skin foams, such as for car steering wheels or hard-wearing seats

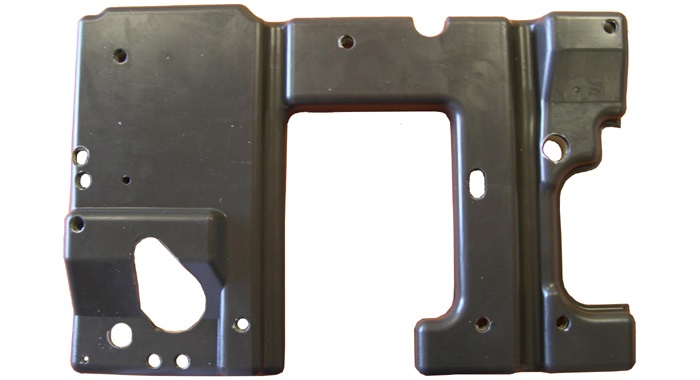

Polyurethane moulding

We have 16 high-pressure machines with a flow ranging from 2 g/s (120 g/min) to 2 kg/s (120 kg/min). This workshop is backed up by a team specialising in developing materials (lab) and methods.

Associated services:

- Parts design

- Tool design

- Painting

- Buying and assembly of components

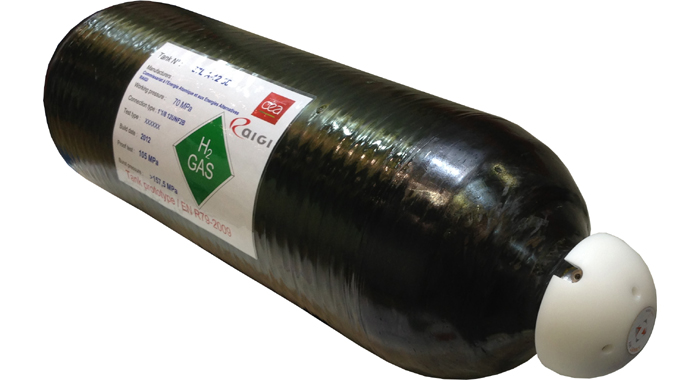

Reservoirs made of (fibre) composites

Sales of reservoirs with a capacity of 24 L and 54 L - type IV - 700 bar

Development of 64 L reservoirs – 700 bar, for 2017

Development:

- We have an exclusive licence with the CEA research institute for rotomoulding of liners by direct overmoulding of the base

- We have also been collaborating with CEA for several years to develop latest-generation type IV reservoirs.

A type IV cylinder for GPL of the kind used in barbecues has been approved in accordance with the EN 14427 standard, and hydrogen cylinders (700 bar) produced in collaboration with Optimum CPV have been approved to the EC 792009 standard.